What problems may be caused by the screw press during use?

1. Damage of screen bucket: the screen bucket is often dehydrated by friction with materials, with high pressure and easy to be damaged after a long time. Generally, 2-3mm stainless steel plate is used to punch the screen barrel, which is not easy to be damaged and has a great relationship with the hardness of the material.

2. Open the welding point of the sieve barrel support: the pressed materials, such as sweet sorghum and sugarcane, need to be thickened and welded firmly.

3. The pressure of the material dehydration and drying layer cannot be increased indefinitely, otherwise the machine may be damaged.

4. The machine cannot press the wrapping layer with kitchen knife, steel plate, drill bit and other items, which is easy to suffocate the screen barrel and seriously damage the screw.

The design key points of the screw press can also be widely used in alcohol plants, fine chemical feed and other industries, as well as the solid-liquid separation of materials containing certain fibers, such as the dehydration treatment of potatoes, bamboo shoots and other materials, such as cassava lees and asparagus raw material residues. ≤ 60% adjustable, its function is different from that of horizontal screw machine, filter press, vacuum suction filter and ordinary screw press, which can make the dehydration rate of waste residue or sludge high, the price low and the application convenient.

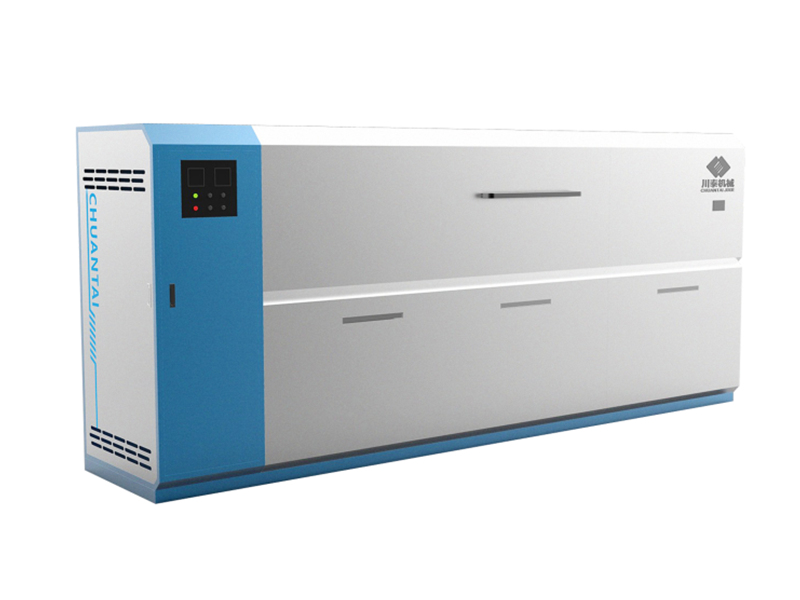

The materials in contact with the materials of the screw press are all high-quality acid and alkali resistant stainless steel. The press is composed of a frame, a transmission system, a feeding part, a juicing part, a hydraulic spring system, a shield and an electrical control part. The pressing screw rotates together with the main shaft, and the material conveying screw is sleeved on the main shaft to rotate reversely with the pressing screw, so that the pressing force on the material is large and uniform. The slag cone is controlled by the hydraulic cylinder spring. Adjusting the oil pressure spring can change the pressure effect of the material.

How to choose the appropriate screw press equipment?

It is very important to choose whether a screw press or a hydraulic press is required according to your pressing purpose. If it is a screw press, you need to buy a single screw press, a double screw press, etc.; If it is a hydraulic press, you can choose a stainless steel press, a fruit press, etc.

Depending on the different properties of the material to be pressed. Different material properties have different applicability to single screw press, including density, shape, temperature, viscosity, particle size, activity, particle size distribution, corrosion, etc.

Different single screw presses have different processing capacity for different time. According to your requirements, select the appropriate press model.

TEL:+86 15336363999

TEL:+86 15336363999

WeChat:gongchris1111

WeChat:gongchris1111

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China